Home | Contact us

Home | Contact us

ACP100 is designed by China Central Nuclear Power Corporation – a 330 MWt pressurized water reactor with integral steam generators and passive core and containment cooling systems. In April of 2016 IAEA issued the world first final safety review report for the SMR. The unit can generate 100 MWe, provide 450 t/h district heating and up to120,000 t/day fresh water.

The sketch provided by (CNNC): FREE DOWNLOAD

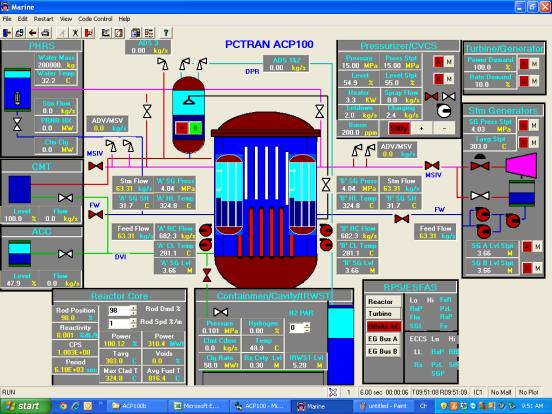

Our PCTRAN/ACP100 has an integral reactor vessel containing 16 once-through steam generators (OTSG) lumping into two, a pressurizer, pressure relief valves for the Automated Depressurization System (ADS), in-containment water tank, core makeup tank, accumulator, steel shell containment and passive residual heat removal system (PRHR) outside the containment.

Both manual and automatic controls are provided for normal operation, transient and accident mitigation.

PCTRAN/ACP100 Simulated Parameters:

Thermal power 310 MWt

Electric power 100 MWe

Coolant inlet temperature 281˚ C

Coolant outlet temperature 324˚ C

Operation pressure 15 MPa

SG pressure 4 MPa

Fresh water production 120,000 tons/day

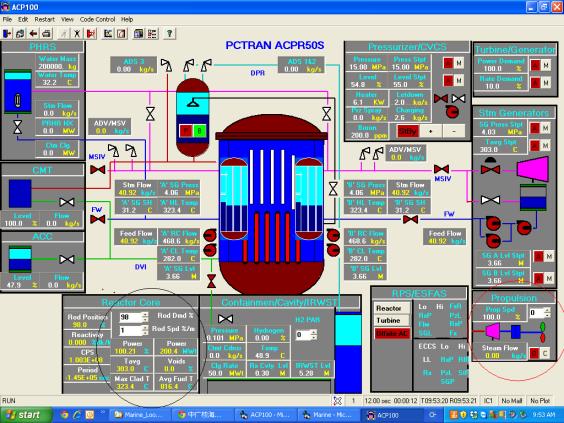

Another model for a marine-oriented version ACPRS50 is developed by China General Nuclear Power Corporation (CGNPC). Its electricity output is 50 MW. A portion of the generated steam drives a separate turbine with speed reduction gears and a clutch to the propulsion unit.

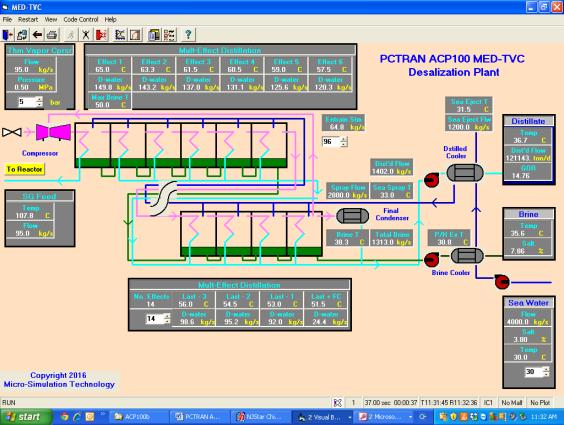

Both are equipped with MED/TVC (Multiple-stage Evaporation Desalination/Thermal Vapor Compression) units. Depending upon the extracted motive steam and sea water condition, fresh water production rated is also computed.

PCTRAN/ACP100 MED/TVC Desalination mimic

Transient Runs

Maximize the operating screen and click “Run” button in the menu bar. Click the upper right “Turbine/Generator” panel’s “Power Demand” “M” for manual button to change the demand to 40% and close it. Resume the run the reactor power will drop to 40% at 10%/min rate. The SMR’s primary and secondary pressures, levels, flow rates, and temperatures will follow smoothly according to ACP100’s design control system logic.

2. Loss of Coolant Accident

A hot leg break is analyzed to show PCTRAN/AP100’s passive ECCS capability. Reactor trip is automatically initiated on low RC pressure. Click on top “Code Control” button and select Malfunction No. 1 for “Hot leg break”, enter 100% for 100 cm2 break and check “Activate” to close the window. Resume the run you will see coolant loss to trip the reactor on low pressure. A loss of offsite power is assumed to trip the RC and feedwater pumps. CMT is automatically initiated on signal of pressurizer low level and the accumulator starts to injection on low pressure. Operator should open the containment cooling system’s isolation valve in the lower-middle “Containment” panel. The following transient figures show recovered RC inventory and containment pressure under control by vapor condensation via the heat exchangers in the outside cooling pool.

3. Station Blackout

A total loss of offsite power is initiated by clicking on the “Offsite AC” button in the lower right “RPS/ESFAS” panel. The reactor coolant pumps and feedwater pumps are tripped. The reactor and turbine trips follow. Operator initiates PRHR cooling by opening the OTSG secondary steam valves to the emergency pool heat exchangers and the condensate return valve. Natural circulation removes the core decay heat and the pool temperature heats up slowly. The amount of the pool inventory is sufficient for cooling up to three days. Makeup of the pool is needed to keep the reactor safe indefinitely.