Home | Contact us

Home | Contact us

Benchmark of the following study was conducted:

"A Study on the Mitigating Capability of an Auxiliary Feedwater System During SBO for APR1400" by Young Choi, K R Kim, KAERI, P.O.BOX 105, Yooseong-Gu, Daejeon, Korea, 305-600

The code used is MELCOR.

The case we benchmarked is the first No-AFW one. Transient plots are shown below:

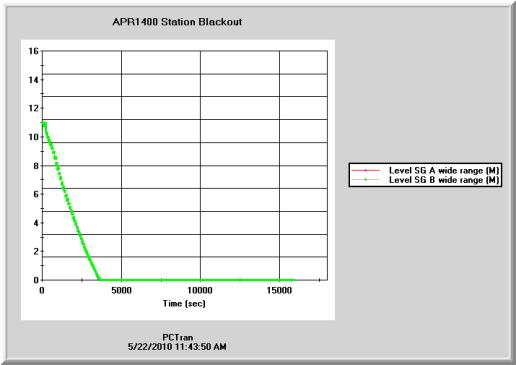

Fig. 1 The steam generator level – dryout in 3,620 seconds, almost identical to MELCOR

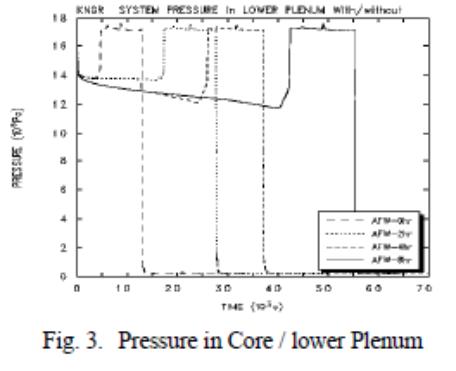

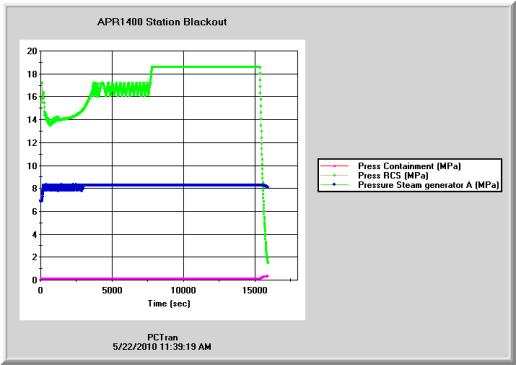

Fig. 2 RCS, SG and containment pressures – RC pressure increases to lift POSRV after SG dryout. Reactor vessel failed at 15,300 seconds as compared to MELCOR’s 12,840 seconds.

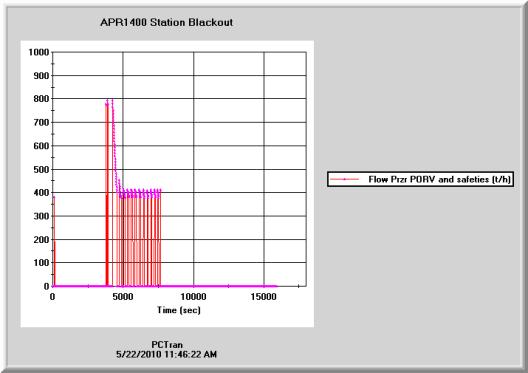

Fig. 3 POSRV relief flow rate – first brief discharge after loss of all feedwater. Then cycled to relief steam and two-phase fluid till vessel empty.

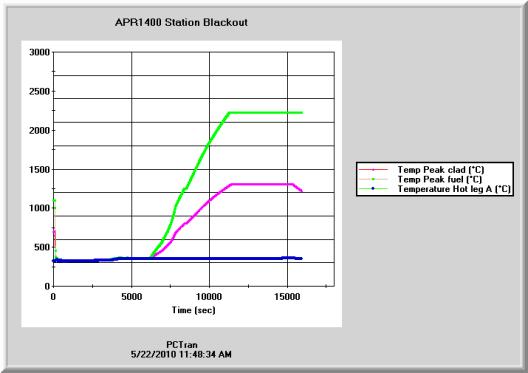

Fig. 4 Core and coolant temperatures – Fuel and clad heated up after uncovery. Melting started around 11,000 seconds.

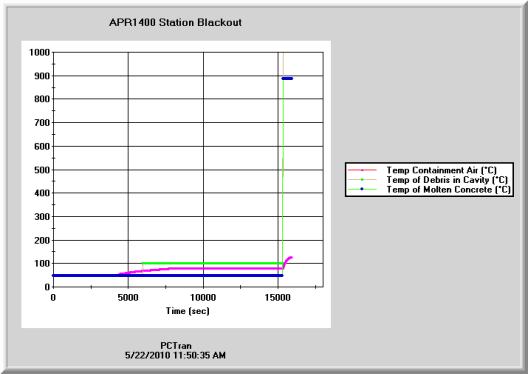

Fig. 5 Containment air and debris temperatures.

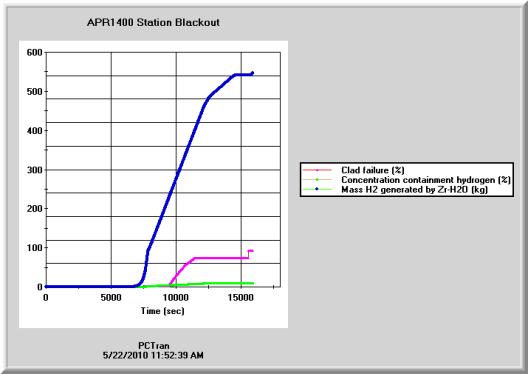

Fig. 6 Total hydrogen generated 550 kg is comparable to MELCOR result of 596 kg.

Timing of SG dryout, core uncovery, vessel dry are almost identical with MELCOR.

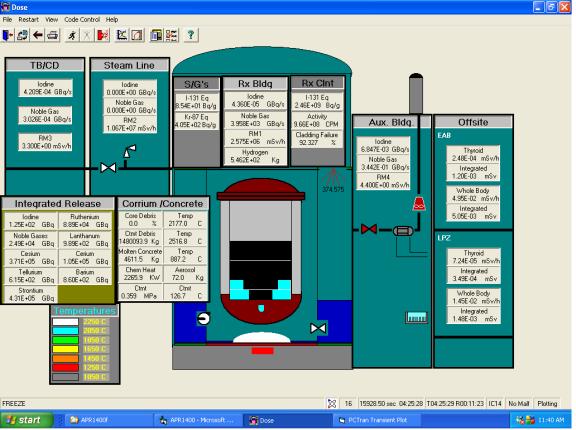

Core collapse time of 13,600 sec and vessel bottom penetration time of 16,300 sec are slightly later than that around 12,840 sec from MECOR. At the end of the run the containment mimic is shown below:

Fig 7 PCTRAN/APR1400 Containment and dose mimic after SBO.

Corium-concrete-interactive (CCI) is ongoing as displayed by the red slab below the debris. For APR1400 the Cavity Cooling System (CCS) can direct water from the In-containment RWST by gravity draining or pumping via the Containment Spray Pumps (CSS) into the cavity. The pump at left and manual control valve at right symbolize operation of CCS. Its function is not presented here because no documented analysis or test report available for benchmark. We already know there is elevated pressure and temperature in the containment (cavity) from Figs. 2 and 5. Pouring water on top of the debris will cause sudden quench or even a steam explosion that may fail the containment. So it is a better strategy to activate the CCS and soak the vessel bottom well ahead before vessel failure. By doing so it should have prevented vessel melting and debris relocation.

PCTRAN/APR is proven to be a tool to complement the state-of-the-art codes such as MELCOR or MAAP to reproduce the severe accident phenomena. Its live and interactive operability enhance design and training in severe accident mitigation.