Home | Contact us

Home | Contact us

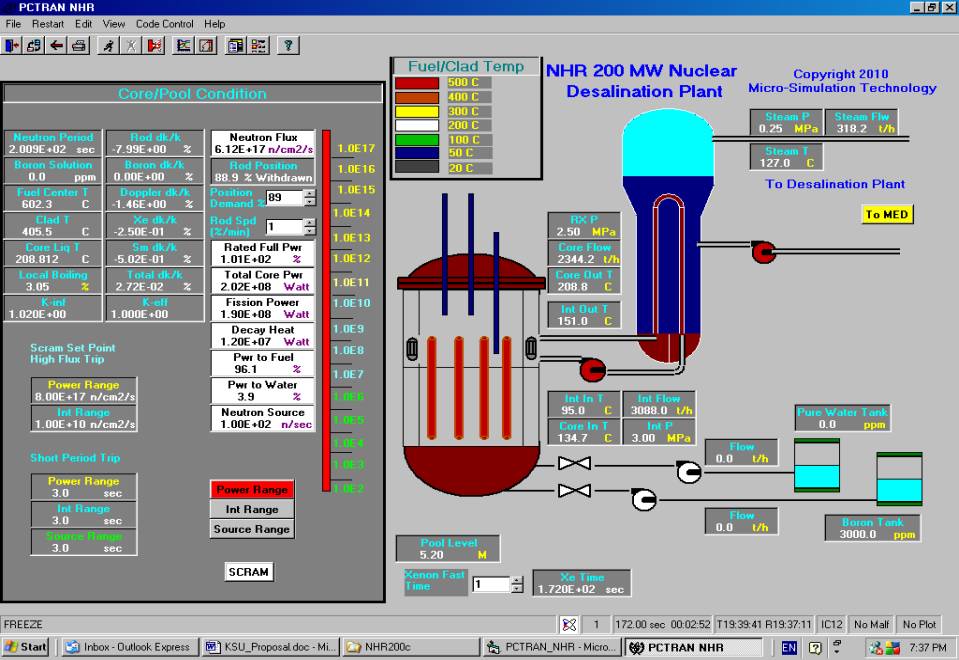

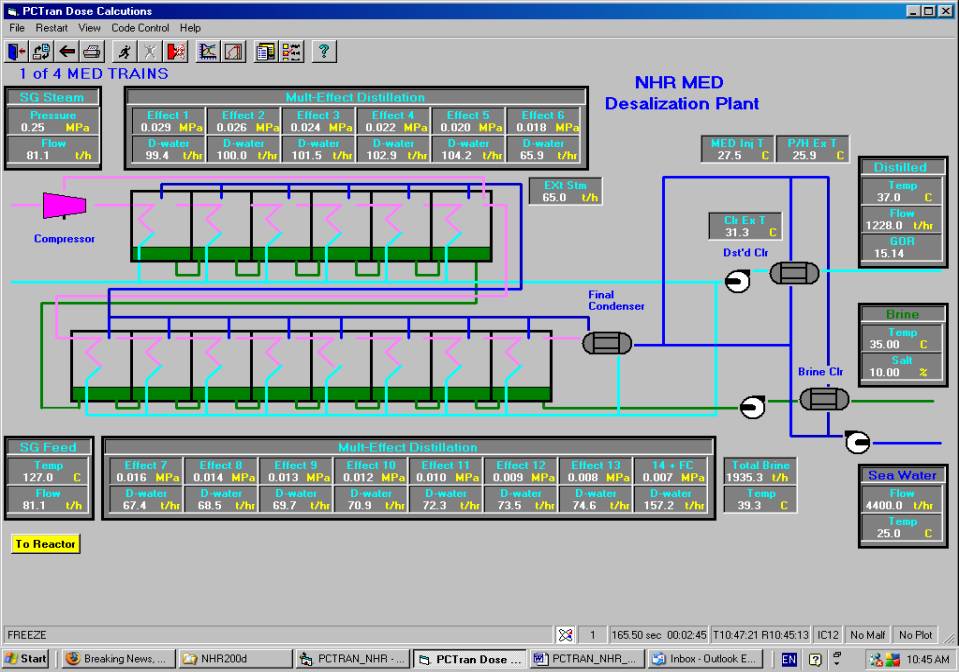

A PC-based simulator based on the 200MW low temperature heating reactor NHR, designed by Tsinghua University of China [1] for desalination was successfully developed. The nuclear plant is coupled with a MED-TVC (multiple effect distillation – thermal vapor compression) unit to generate distilled water. Point kinetics is used to solve core power evolution from cold to critical and power conditions. The nuclear plant generated steam is directed to four parallel units of MED-TVC. Using fourteen vacuum chambers (effects) to evaporate the steam with a compressor, this MED-TVC process reaches a gain output ratio (GOR or distilled water production / nuclear steam rate) over 15. The fresh water production is 120,000 tons per day. The software is written in Microsoft Visual Basic and works in Windows environment.

The nuclear plant operates at low primary coolant pressure of 2.5 MPa. The core flow goes through heat exchangers in the downcomer of the vessel by natural circulation. The intermediate coolant is maintained at a higher pressure of 3.0 MPa. It goes outside the vessel into a steam generator. So any pipe break will keep radioactive material inside the vessel. Steam is produced in the steam generator at pressure of 0.25 MPa and 330 t/hr rate.

The desalination plant is conventional MED-TVC process. Steam from the nuclear plant is directed through a compressor nozzle to enter the first chamber’s tubes at about 68ºC (0.027 MPa). It is enhanced by steam extraction from the 6th effect to reach higher thermal efficiency. Seawater is pumped and sprayed into the chambers in the opposite direction. Condensation in each effect is collected and recirculated to the next chamber to use its latent heat. Portion of the condensate is fed back into the steam generator. Uncondensed salt water (brine) is also directed to the next chamber to pass its heat content. There are heat exchangers to pre-heat the sea water and cool the brine and distilled water production. Standard calculation in the code verifies the pure water production from this unit (one of four) is about 1,250 t/h.

Having completed the prototype, we have developed another kind, the MED– VTE or vertical tube evaporation process. Design alternatives can be easily considered for optimal performance. The simulator is aimed for training and design for regions short of fresh water. The tool will also help economic feasibility and cost studies.

1. JIA Haijun, ZHANGYajun, INET, Tsinghua University, Beijing, China, “Nuclear Seawater Desalination Plant Coupled with 200 MW Heater Reactor”, “Symposium on Peaceful Applications of Nuclear Technology in the GCC Countries, Jeddah 2008.