Home | Contact us

Home | Contact usMicro-Simulation Technology

In cooperation with

National Tsinghua University

November 2009

The Taiwan Power Company’s ABWR Lungmen Project Unit 1 will soon be completed and ready for startup. PCTRAN simulation software was started over 10 years ago with initial objective for use in emergency planning. In that direction the FSAR cases and later severe accidents are covered. However, the immediate task at Lungmen is stable and smooth startup to criticality. Then bring the turbine/generator online and conduct a series of tests during power escalation. All plant control and supporting systems must be well tested before full-power commercial operation. The operators of course have long been trained both in classroom and at the replica simulator. On the other hand, other personnel of Taipower as well as students of Tsinghua University should also get familiar with this process. Therefore we extend PCTRAN to cover the startup process. Since shutdown (and cooldown) is reverse of the startup process, we also cover it here.

Starting up from cold requires a neutron source and flux escalation over many decades (multiples of ten). For neutronics it requires six delayed neutron groups and 11 gamma decay groups. PCTRAN/TRIGA has that capability. Here using a simplified one-group delayed neutron equation the power(flux) is only valid close to criticality (keff = 1). Still most of the scenarios during startup/shutdown are reproduced. These include:

These are in fact common to all BWR’s including Taipower’s Plant 1 and 2. So learning this is beneficial to non-operators Taipower personnel as well as Tsinghua students.

By consulting the plant procedures for manual shutdown and startup, we have successfully simulated this process in five sections:

The first attempt was completed using PCTRAN in British Units. Another one using Lungmen’s metric system will soon be conducted.

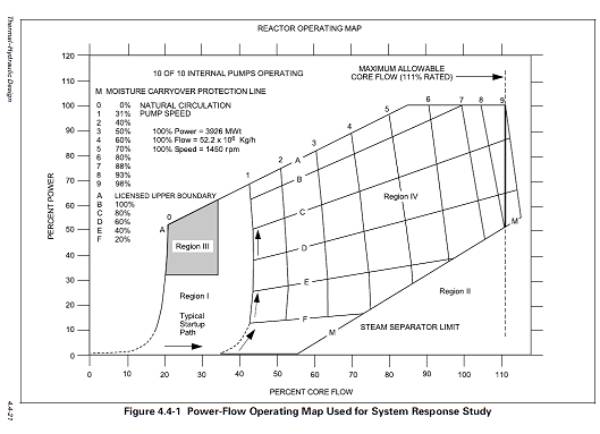

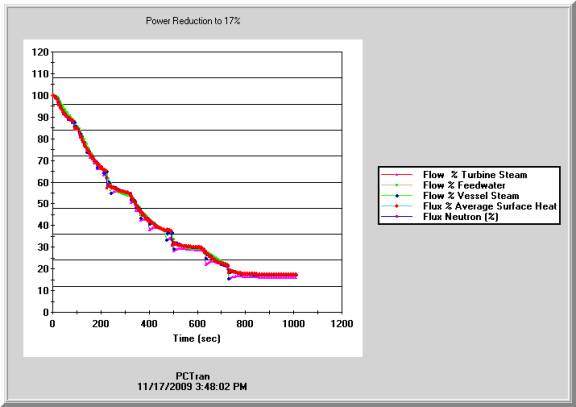

Use the flux/flow map, user can reduce the power using the rod and flow controls in a staggered way.

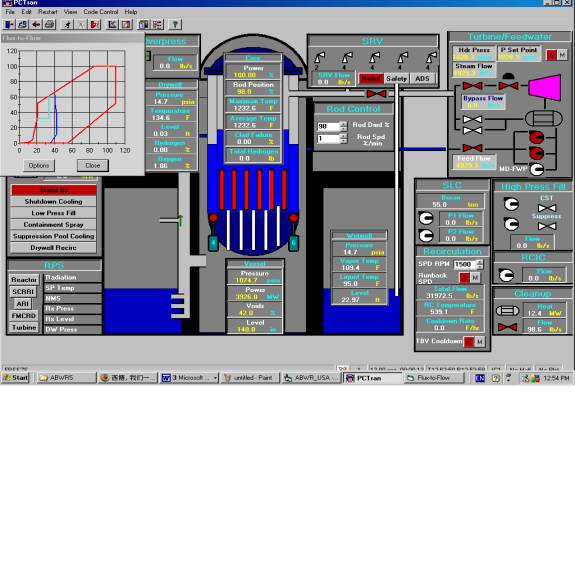

In PCTRAN/ABWR revised mimic, there is a “Rod Control” at middle right of the vessel. User can spin a rod demand in % withdrawn and demand speed in %/min. The rods will move to match the demand at the given rate. The power will change up or down in the flux/flow map accordingly if the core flow rate stays constant. Similarly if the flow demand is varied, user can spin the speed RPM or click the “A/M” auto/manual button and type in a speed demand. The operating point in the map will move diagonally (since both flow and power will change). The operating point must be in the desired zone all the time according to the procedure.

In order to reach a lower power, one can easily set the rod demand somewhat randomly lower than the current position and watch the power drops. As soon as the power approaches the target, he or she should flip the speed demand from 1 %/min to zero to stop the rod movement. Bear in mind the actual ABWR plant has a rod insertion pattern that operators should follow. PCTRAN uses a point-kinetic core model in that the withdrawn fraction corresponds to a given reactivity according to a table. Nevertheless it serves the purpose well for training.

By continuing inserting the rods we have saved states of 80% and 75% power with 100% flow and one for 20% power and 38% flow. Those are test states in the Lungmen Startup Test Matrix for conducting various tests.

Continue inserting the rods below 20% power to around 15%, we are ready to disconnect the turbine/generator and place the ABWR into Hot Standby. Hot Standby is defined as the reactor is critical but steam is bypassed to the condenser without turning the turbine or generating electricity. This is conducted by a simple click on the lower left “Turbine” button in PCTRAN. We should witness the turbine stop valve closed and turbine’s color turned from pink to blue. The control for the feedwater maintains the reactor water level stable at its set point. The TBV pressure control system maintains the header pressure at desired set point.

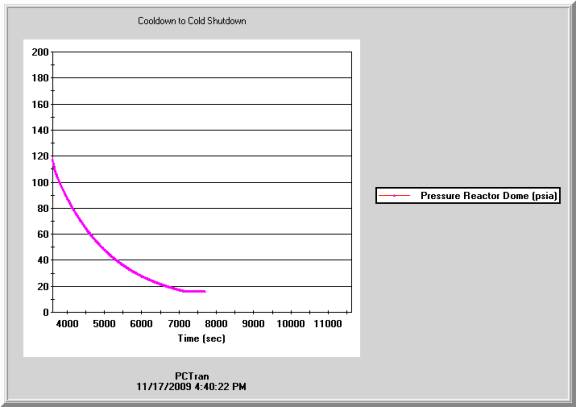

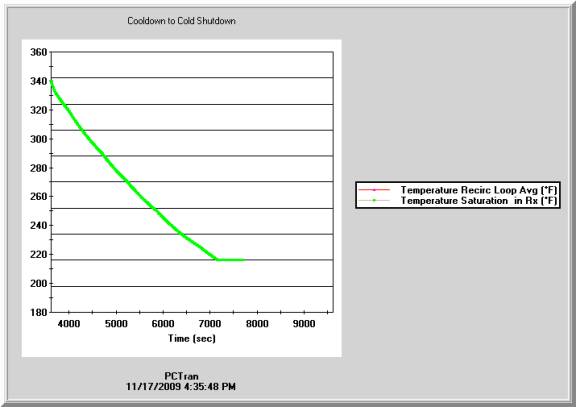

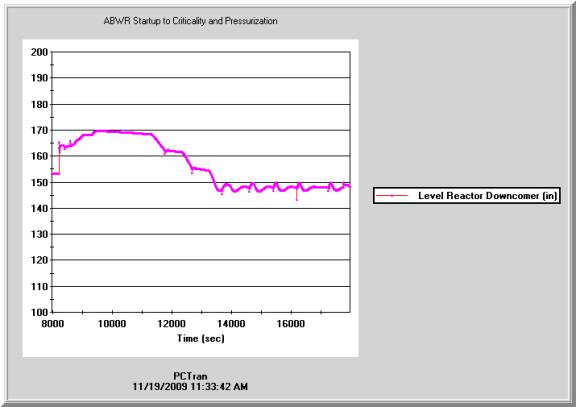

From previous saved IC for hot shutdown condition, turn on all 10 RIP’s and set their speed to 31% minimum. Then use the TBV pressure control or PCTRAN-provided automatic cooldown rate control in the 2nd left lower right panel to type in 80ºF/hr rate. The rate must be lower than Tech Spec limit of 100ºF/hr in any one hour period. The plant is cooled down as shown in the following plots. The level is controlled at 148 inches TAF. Note at the RX pressure is lower than 150 psia, the Shutdown Cooling Mode cut-in pressure, FW is isolated and the RHR system in SDC mode is initiated to continue cool down to cold shutdown mode. A simple click at SDC starts this. One can use one, two or all three pumps to control the rate.

4. Pulling Rods from Cold Shutdown to Criticality (Hot Standby)

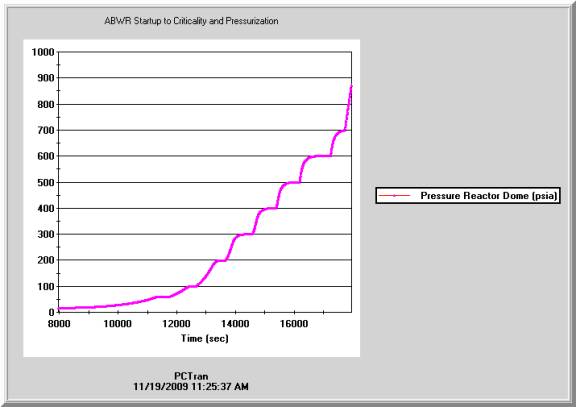

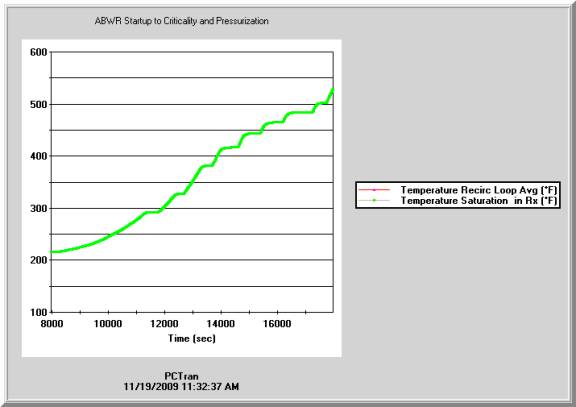

Start the run from previously saved cold shutdown IC33 with Tavg = 216ºF and reactor dome pressure 16 psia and RHR in standby condition. All 10 RIP’s are running at their minimum 30% speed. MSIV is open and the MD FWP is running. There is a rod-insertion pattern for shutdown. Pulling the rods follows the sequence in reverse. For PCTRAN the point core uses only the reactivity value, so its position is represented by percentage of all rods withdrawn. The rod current position is 67%. We click the rod demand percent higher than that with a speed in percent per minute rate.

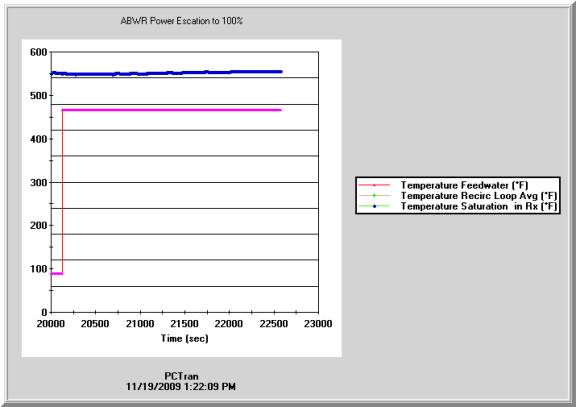

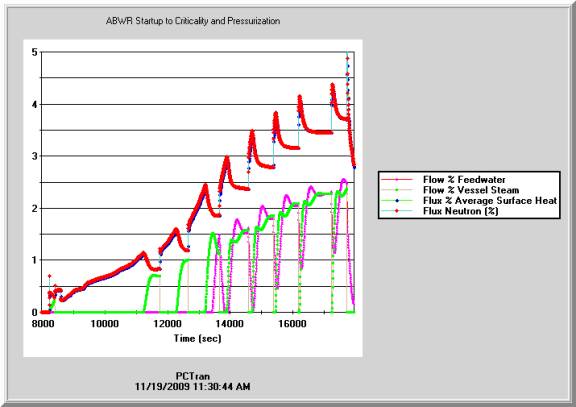

When the rod position reaches 78% the neutron flux shows slight positive number that indicates criticality. Immediately we should stop rod movement. The reactor remains critical and enters into stand-by mode. According to the startup procedure we should raise the vessel pressure and temperature into hot standby mode. The operation condition for connecting the turbine/generator is around 960 psia. The heatup rate must be less than 100ºF/hr for any given hour. We conduct that in PCTRAN by raising the turbine header pressure setpoint by 100 psi a time. We should also monitor the water level, feed and steam flows during this process.

We may also do it alternatively by clicking on the “Cooldown Rate” demand and enter a negative rate (i.e. heatup) in the “Recirculation” panel.

At hot standby condition we resume pulling rods to raise the power above 15%. There we can bring the turbine online by simply click the “Turbine” button and witness the turbine stop valve opens and turbine color pink. The feedwater is then heated by the extraction steam. So we should go to “Malfunction” and deactivate MF14 of “loss of FW heating”.

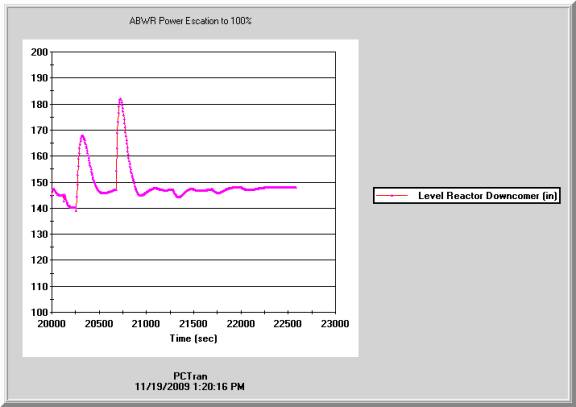

The rod position now is about 86% in PCTRAN. We should pull it slowly and raise the power above 25%. At that point we should trip off the MD-FWP and turn on one main feedwater pump. One MFP has much larger capacity than the MD-FWP so the reactor water rises momentarily above the desired set point of 148” TAF. There is a high level L8 turbine trip at 189” TAF. So we should observe the 3-element FW controller to settle the level back to 148” before turning the 2nd MFW pump on. Both are required for power above 60% to full power operation.

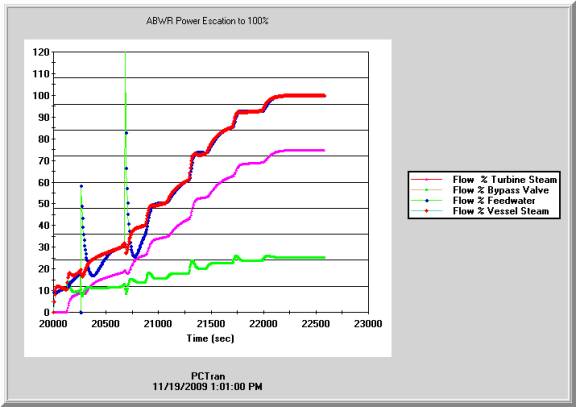

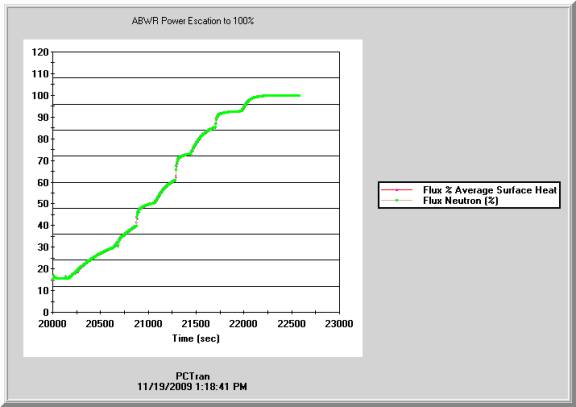

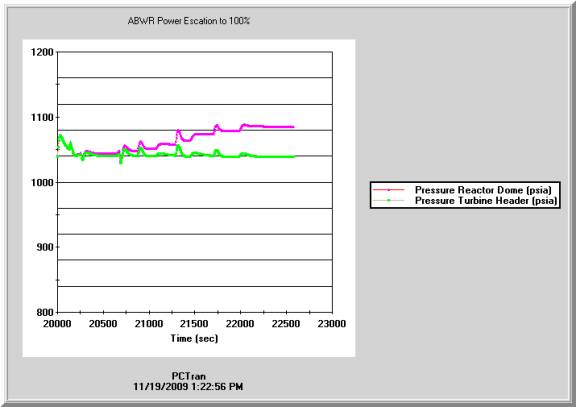

Then the operation map should be checked to raise the power by alternative RIP speed demand increase and rod withdrawal. The speed demand is raised from 30% to 50%, 80%, and finally 100%. In between the rods are pulled to 88%, 90%, till 99%. The power is seen to reach 100% finally.