Severe Accident Model

Micro-Simulation Technology

Revised January 2008

Introduction

We have successfully expanded the PCTRAN model of GE BWR5 to cover

severe accidents. A severe accident is defined as one beyond

design-basis with significant core damage and containment failure.

A borderline is usually set in probability safety assessment (PSA)

as Division 2 at the top-of-active fuel (TAF) uncovery, and

Division 3 for fission product relocation. Our previous models

have covered core heatup and hydrogen generation by metal-water

reaction. For BWR's with inerted containment, hydrogen burn is

not possible. But leakage pathways through the containment system

may release significant radiological material to the atmosphere.

It is important to simulate these phenomena for training and

emergency planning. Download

Core Model

The core is modeled into six vertical nodes. Each one generates a

portion of the decay heat after shutdown. When the boundary heat

removal rate is less than the core heat, the core node is heated

up to the point of melting. Molten fuel may collapse into the

bottom of the vessel. The vessel lower head may then heat up to

the melting point, too. The molten debris may drop into the

drywell cavity floor. During the fuel damage process, first the

fission gas in the clad may leak out. Later if the fuel and

cladding continue their degradation, fuel isotopes will release

also. In addition to iodine and noble gases, there are alkali

metals, tellurium, barium, cerium, lanthanides, etc. The elevated

concentration of these radioactive isotopes would find their ways

through the vessel break, relief valves, and containment leakage

into the environment.

PCTRAN core model

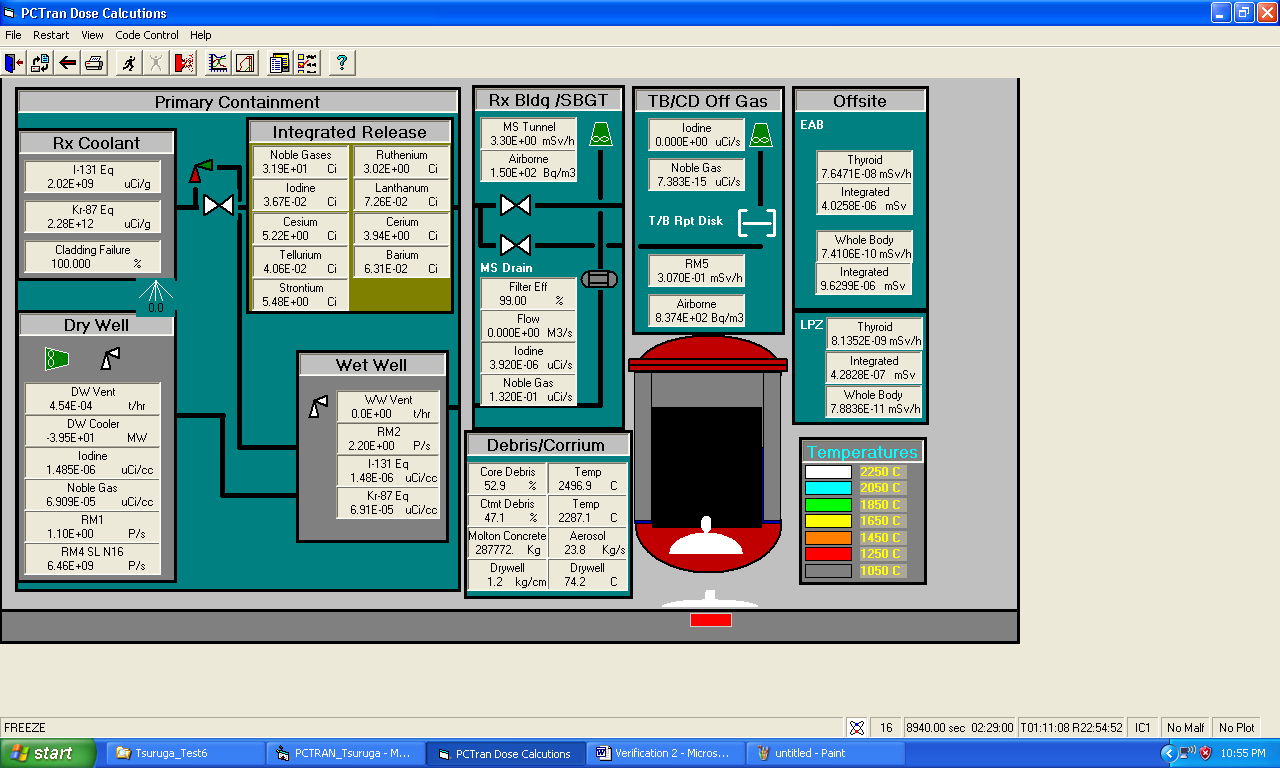

PCTRAN BWR5 plant mimic with Mark II containment

Verification Runs

There are basically two types of severe accidents: 1) low reactor

pressure starting from a loss-of coolant accident (LOCA) and 2)

high pressure starting from reactor isolation; reactor scram was

assumed successful for both. Part of all ECCS must be assumed to

be lost or the consequence would not be severe enough to expose

the core. The third kind is anticipated transient without scram

(ATWS). That will be analyzed separately later.

1. LOCA

In conducting a test run, you can initiate a large break LOCA,

e.g. 2000 cm2 recirculation loop break for the BWR. With

continued feedwater and automated initiation of ECCS, the core

will soon be reflooded and no significant clad damage is expected.

So we purposely disable the feedwater and all ECCS trains. For

BWR5 there are HPCS, RCIC, LPCS and RHR in the LPCI mode. We

disable them all by either tripping the respective pumps or

closing the isolation valves.

The water level in the vessel then drops rapidly and soon exposes

the fuel. You should click the "View" button in the top menu bar

and choose "Dose mimic". Following is a display at about 3600

seconds after the break - the point of initial core-melt of the

BWR.

PCTRAN Dose Mimic at Core-melt Start Following a LBLOCA Without ECCS

Since core-melt is usually a slow process, you can click on the

fast time speed multiple to accelerate the run. If it is still

too long a wait to reach advanced stage of severe damage, you can

click at the "Restart" button in the menu bar and select one of

the previously saved IC's. Resume the run at that point you can

verify the core node temperatures, extent of clad damage,

radiation monitor readings and fission product release source

terms. You can check the key variables' trending by going to

"View", "Transient Plot" as before. The integrated release of

iodine, noble gases, and heavy elements are shown in the panel

inside Reactor Building. Major pathways are through the primary

containment leakage, drywell and wetwell vents, MSIV and bypass to

the low-pressure turbine rupture disk, the standby gas treatment

system (SGTS) in the Reactor Building, etc. A further

introduction of malfunction in anyone of these will aggregate the

release and instantly reflected in the source terms. Using the

dispersion factors X/Q from the plant's Final Safety Analysis

Report (FSAR), the projected doses at the site Exclusive Area

Boundary (EAB) and Low Population Zone (LPZ) are displayed.

Further melting without ECCS water will lead core collapse to the

vessel bottom. Shown below at about 6300 seconds is a diagram as

the core collapsed. The vessel bottom steel is then heated up to

melt, too. Debris is then dropped on to the drywell floor.

If the emergency power is resumed, e.g. the drywell spray is

available and turned on by the operator, it will immediately cool

the debris as shown by changed color from white (over 2250C) to

gray (under 900C).

Core-Concrete Interaction Model

In the event that the molten core heats up the vessel bottom and melts through it, the debris falls into the reactor cavity (drywell pedestal for BWR). It is called corium as the metal interacts with concrete and form a slump. At lower temperatures, degassing of concrete occurs and both steam and carbon dioxide can be released. At higher temperatures concrete can also be melt and mixed with metals. Since concrete is normally formed by Ca, Fe, Si, Al, Na, Mg, Mn, Cr, etc. with variable compositions. Typical fractions are:

Mass fraction of concrete |

Component |

0.3288 |

|

CaO |

0.357 |

|

SiO2 |

0.067 |

|

Al2O3 |

0.0533 |

|

H2O |

0.1939 |

|

CO2 |

The most important reactions are:

Fe + CO2 -> FeO + CO + Q1

Fe + H2O-> FeO + H2 + Q2

Ni + H2O -> NiO + H2 + Q3

Zr + H2O -> ZrO2 + H2 + Q4

2 Cr + 3 H2O -> Cr 2O3 + 3 H2 + Q5

Each reaction rate is temperature-dependent and given by the parabolic law:

K = R5 exp (-G/T) (kg/M2)2/sec, T in Kelvin

To keep track of every reaction is too tedious for a simplified code. Therefore we lump all them together into a single form similar to the above Zr-H2O or Zr-O2 equations. Leaving the reaction rate and exothermal heat as typical values for adjustment.

In the core Zr-water reaction calculation, cylindrical geometry has been used for vertical tube bundle configuration. For CCI it is instead a semi-hemisphere configuration to represent the slump pile of debris. The top hemisphere interacts with atmosphere above, and the bottom flat surface interacts with concrete floor. A red slab represents the molten pool of concrete in the mimic display. Following are dose mimics for BWR and PWR plants respectively.

Vessel Penetration with Debris in the Drywell Floor

The concrete penetration depth is limited by the corium temperature decrease during a transient. As soon as the corium temperature is reduced to below the reaction threshold temperature, the reaction is stopped. Another limit is the total amount of core mass. As soon as the whole core dropped into the containment has completely reacted with concrete, no further actions are possible. Whichever comes first will stop further propagation of CCI. Heat generation by CCI is not explicitly displayed or tracked as an output variable, since there is no way to be verified or benchmarked against experimental or other code predictions.

Verification Runs

There are basically two types of severe accidents: 1) low reactor pressure starting from a loss-of coolant accident (LOCA) and 2) high pressure starting from reactor isolation; reactor scram was assumed successful for both. Part of all ECCS must be assumed to be lost or the consequence would not be severe enough to expose the core. The third kind is anticipated transient without scram (ATWS). That will be analyzed separately later.

1 LOCA

In conducting a test run, you can initiate a large break LOCA, e.g. 2000 cm2 recirculation loop break for the BWR. With continued feedwater and automated initiation of ECCS, the core will soon be reflooded and no significant clad damage is expected. So we purposely disable the feedwater and all ECCS trains. For BWR5 there are HPCS, RCIC, LPCS and RHR in the LPCI mode. We disable them all by either tripping the respective pumps or closing the isolation valves.

The water level in the vessel then drops rapidly and soon exposes the fuel. You should click the “View” button in the top menu bar and choose “Dose mimic”. Following is a display at about 3600 seconds after the break - the point of initial core-melt of the BWR.

Since core-melt is usually a slow process, you can click on the fast time speed multiple to accelerate the run. If it is still too long a wait to reach advanced stage of severe damage, you can click at the “Restart” button in the menu bar and select one of the previously saved IC’s. Resume the run at that point you can verify the core node temperatures, extent of clad damage, radiation monitor readings and fission product release source terms. You can check the key variables’ trending by going to “View”, “Transient Plot” as before. The integrated release of iodine, noble gases, and heavy elements are shown in the panel inside Reactor Building. Major pathways are through the primary containment leakage, drywell and wetwell vents, MSIV and bypass to the low-pressure turbine rupture disk, the standby gas treatment system (SGTS) in the Reactor Building, etc. A further introduction of malfunction in anyone of these will aggregate the release and instantly reflected in the source terms. Using the dispersion factors X/Q from the plant’s Final Safety Analysis Report (FSAR), the projected doses at the site Exclusive Area Boundary (EAB) and Low Population Zone (LPZ) are displayed.

Further melting without ECCS water will lead core collapse to the vessel bottom. Shown below at about 6300 seconds is a diagram as the core collapsed. The vessel bottom steel is then heated up to melt, too. Debris is then dropped on to the drywell floor.

If the emergency power is resumed, e.g. the drywell spray is available and turned on by the operator, it will immediately cool the debris as shown by changed color from white (over 2250°C) to gray (under 900°C).

Micro-Simulation Technology is currently working on a model for debris-concrete-interaction (CCI). The interaction will generate further heat and aerosols that may also get released into the atmosphere.

At end of a run, you can check “yes” if you want data of operations and dose release saved. A new database DoseData.mdb is generated that can be directly used by dose projection codes for area dose projection. A sample table is listed below.

Radiological Release Source Terms in Curies versus Time in Seconds

TIME I N.G. Ce Te Sr Ru La Ce Ba

8940 1.05E+03 1.33E+05 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+0

9000 1.06E+03 1.34E+05 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+0

9060 1.06E+03 1.34E+05 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+0

9120 1.09E+03 1.36E+05 9.98E+02 1.56E-01 0.00E+00 2.29E-02 1.26E-03 8.37E-03 3.64E-0

The tabulated data is stored in either Excel or Access form and available for printing and/or plotting during an exercise. This data can easily be fed into any real-time meteorological dispersion software for dose projection.

Fig. Large Break LOCA Reactor Pressure (Mpa) vs. Time (hr)

Fig. Small Break LOCA Reactor Vessel Level (m TAF) vs Time (minutes) Fig. Small Break LOCA Reactor Vessel Level (m TAF) vs Time (minutes)

Fig. SBLOCA Reactor Dome Pressure (Mpa) vs. Time (min)

Fig. Mid-size LOCA Reactor Vessel Water Level (m TAF) vs. Time (hr)

Fig. Mid-size LOCA Reactor Vessel Pressure (MPa) vs. Time (hr)

Fig. Mid-size LOCA Break Flow (kg/s) vs. Time (hr)

Fig. Suppression pool water temperature (K) after ATWS (hours)

Fig. SRV flow vs. time (hr) after ATWS

Resumption of Containment Spray to Quench the Debris

At end of a run, you can check "yes" if you want data of

operations and dose release saved. A new database DoseData.mdb is

generated that can be directly used by dose projection codes for

area dose projection. A sample table is listed below.

Radiological Release Source Terms in Curies versus Time in Seconds

| TIME | I | N.G. | Ce | Te | Sr | Ru | La | Ce | Ba |

| 8940 | 1.05E+03 | 1.33E+05 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+0 |

| 9000 | 1.06E+03 | 1.34E+05 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+0 |

| 9060 | 1.06E+03 | 1.34E+05 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+00 | 0.00E+0 |

| 9120 | 1.09E+03 | 1.36E+05 | 9.98E+02 | 1.56E-01 | 0.00E+00 | 2.29E-02 | 1.26E-03 | 8.37E-03 | 3.64E-0 |

The tabulated data is stored in either Excel or Access form and

available for printing and/or plotting during an exercise. This

data can easily be fed into any real-time meteorological

dispersion software for dose projection.

2. Reactor Isolation (High Pressure) Event

A station blackout event (SBO) will lead to reactor isolation at

high pressure. Without AC power the high pressure core spray

(HPCS), RHR pumps for LPCI and containment spray, and low pressure

core spray (LPCS) are all disabled. The only passive devise

available is the steam-driven reactor coolant isolation cooling

(RCIC) system. Since its low capacity it is not sufficient for

coolant loss through the cycling SRV's. In the following mimic we

started the transient by closing the MSIV and trip all feedwater

pumps. The reactor soon scrammed and the recirculation pumps are

tripped automatically. At reactor water dropped to L2 the high

pressure HPCS and RCIC started automatically. We disabled them

for simulating this event. Later when the water level dropped to

L1 the low pressure LPCI and Core Spray started. We also disabled

them.

Station Blackout

Steam relief into the suppression pool would heat up the pool

and pressurize the wetwell. As the wetwell pressure is greater

than that of the drywell by 0.035 bar, the vacuum breakers opened.

It is witnessed by the green breaker hinge swing open and turns

into red. So the drywell pressure also increased. When it

increased to the high DW pressure set point of 1.25 bar with the

reactor water level below L1, the Automatic Depressurization

System (ADS) started to open two sets of SRV's. This may not

happen since the RHR pumps were not available to refill the

vessel. Here we allowed ADS to depressurize the vessel.

After that the transient is similar to that of LOCA with core

heatup, meltdown, vessel penetration and debris falling into the

drywell. The containment continued to heat up until eventual

failure.

Shown below are transient plots of reactor pressure, drywell and

wetwell pressures, water level in the core, and peak fuel, clad

and water temperatures. They are all reasonable as expected for

the SBO event. They are also consistent with predictions from

other methodologies such as NUREG 1150 and MAAP code.

Conclusion

Since every BWR5 plant is highly plant specific, especially in the

release pathways and radiation monitoring system. MST is

experienced to model them as soon as a specific plant's layout and

data are available. The simulation prediction will then be

verified against other severe accident predictions. Since a

real-life severe accident has hardly ever happened, usually there

are two sources of data: 1) the Vendor's (GE/Hitachi/Toshiba)

Owner's Group Severe Accident Management Guidelines (SAMG), and 2)

MAAP or MELCOR computer runs. MST will conduct benchmark runs

against these two and ensure adequate prediction is resulted.

In summary, the severe accident capability expands PCTRAN

immensely to cover the worst possible scenarios. The generated

radiological release provides the source term for environment dose

projection. Using this tool to thoroughly investigate the possible

failure paths, you can develop the most effective mitigating

procedures. It is the ultimate tool for plant safety and

protection.

|