AREVA EPR 1600

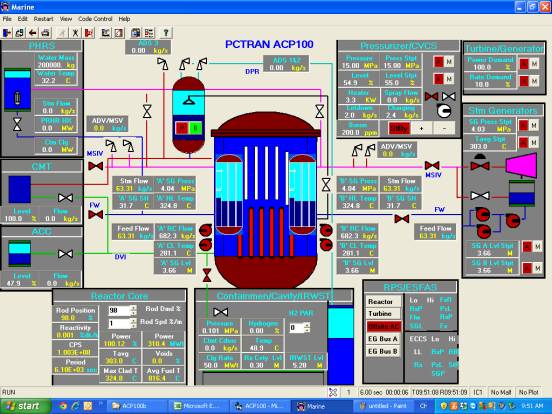

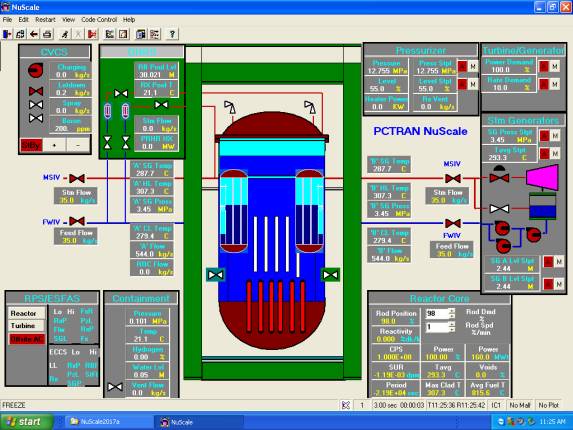

The French-German cooperation AREVA designed the third generation plus of advanced PWR EPR is modeled in PCTRAN. The reactor thermal power is 4300 MW (1600 MW electric). There are four trains independent emergency core cooling systems and double containment for improved safety. The large components such as the pressure vessel and its internals, the steam generators and the primary coolant pumps assure modest response during disturbance from normal operation,

The four-loop PWR plant is modeled by a single loop with the pressurizer and the other three loops lumped together. The reactor and SG control are on the right and ECCS is on the left of the mimic. Go to download for a hand-on operation of the newest EPR and witness its dynamic response to transients and accidents. Download the free demo.

The Safety Injection System (SIS) is actuated on low-low pressurizer pressure. It starts MHSI and LHSI pumps (the US EPR does not have HHSI pumps) and initiates a partial cooldown of the secondary system. The main steam relief train (MSRT) depressurizes a SG at a controlled rate by changing the pressure set point from the post-trip value of 1385 psia to 870 psia in approximately 20 minutes. The corresponding cooldown rate is 180ºF/hr (100ºC/hr). This depressurization results in a reduction in the RCS pressure is low enough to enable the needed MHSI injection while still high enough to prevent core recriticality.

MSRT can be initiated relatively easily in PCTRAN. A single click on the Tavg control button and typing in the desired cooldown rate of 180 ºF/hr (100ºC/hr) starts the sliding cooldown. When the SG pressure is down to 870 psia (saturation temperature about

530º F), another click at the pressure set point switches to constant pressure control. Showing below PCTRAN achieves this flawlessly.

If a core-melt accident should nevertheless occur despite all of the accident prevention measures deployed, the molten core material (corium) would be collected and cooled in a specially designed spreading area located underneath the reactor pressure vessel but still inside the containment.

Verification Sample Runs

Steam Generator Tube Rupture

The AREVA document ANP-10263NP-A “Codes and Methods Applicability Report for the US EPR” was benchmarked using PCTRAN/EPR. The case first chosen is a steam generator tube rupture. The sequence of event is:

The transient plots are shown below. Every individual PCTRAN plot follows the corresponding AREVA one using the same units and scales as possible. “A” is the ruptured loop and “B” is the intact 3 loops combined.

PCTRAN RC pressure repressurization is caused by MPSI initiation and throttling back that was not in the AREVA analysis.