Home | Contact us

Home | Contact us

Westinghouse has submitted a Final Safety Evaluation Report (FSER) and USNRC approved it in 2005. For a complete spectrum of loss-of-coolant-accidents (LOCA), the core is never uncovered. PCTRAN has basically reproduced these results with comparable pressure, temperature and water inventory transients. The CMT, accumulator, and ADS systems work well to depressurize the RCS and provide coolant makeup. The PRHR heat exchanger removes the decay heat. The passive containment system supplies coolant from the highly located WST that enhances natural air draft cooling by the atmosphere. These phenomena are quantitatively demonstrated with vivid graphics and animation. It is therefore an indispensable tool to supplement text material for a comprehensive AP1000 training program.

No attempt was made to match each of the PCTRAN analysis with the design document perfectly. Instead the input and sequence of events were prepared to be agreeable with the base case as close as possible; then simply let the code, i.e. the physical laws governing the algorithm to take its course. The results are compared side-by-side for evaluation.

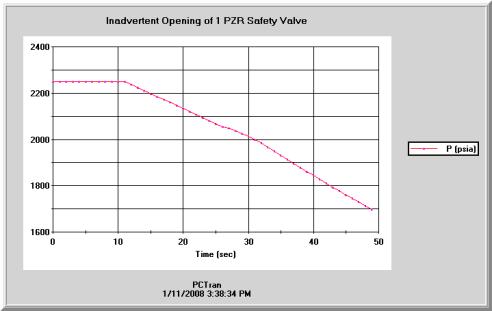

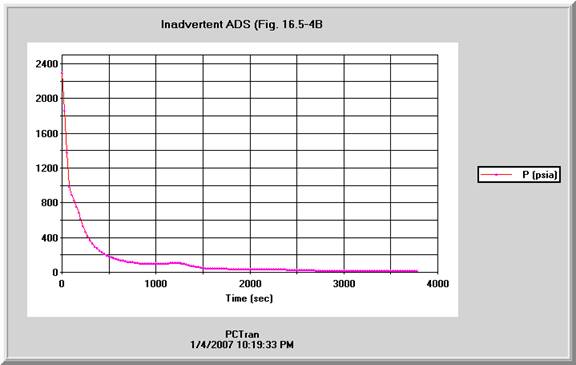

The case of inadvertent ADS initiation by opening one of the first stage valves was analyzed. The reactor is then tripped on low pressure and the "S" signal tripped the reactor and coolant pumps, started the CMT and accumulator injections. Second and third stage ADS valves opened 70 seconds and 190 seconds respectively after initiation. The fourth-stage ADS opened to the containment at the CMT level down to 20% level. Eventually the RCS is depressurized to allow IRWST water to drain down by gravity to refill the core. The entire transient agrees closely with FSER Section 15.6.5-4B.

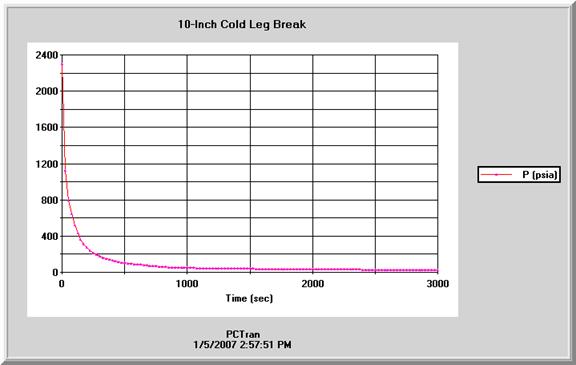

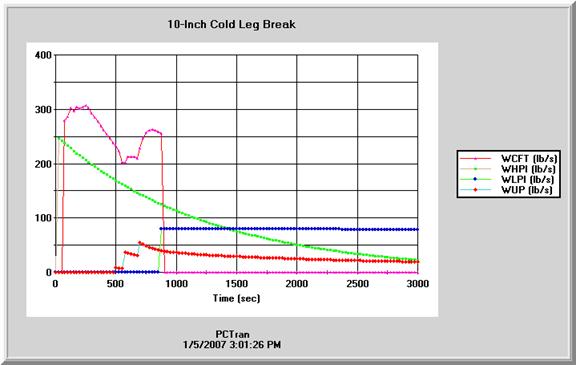

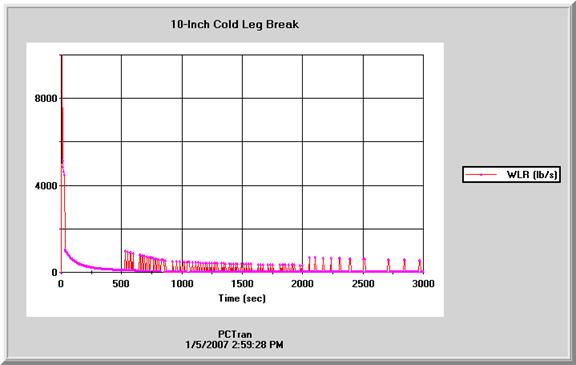

10-Inch Cold Leg Break

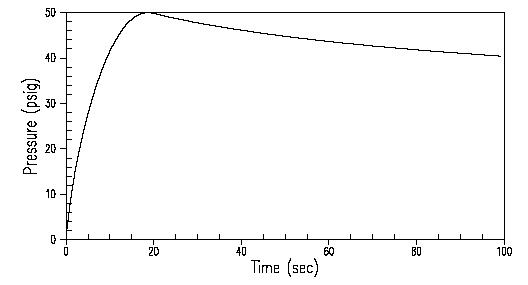

A 10-inch (500 cm2) cold leg break is initiated. After the reactor trip on low pressure and containment high pressure "S" signal, the coolant pumps trip, steam generator isolation, start of the CMT, PRHR, accumulators and ADS occur subsequently. PCTRAN's results are shown in the following figures. The break discharge soon turns from liquid to two-phase as the cold leg is exposed. It is witnessed by the break specific enthalpy. Comparison with FSER Case 15.5.5.4B- shows basic agreement. There is no core exposure and heatup.

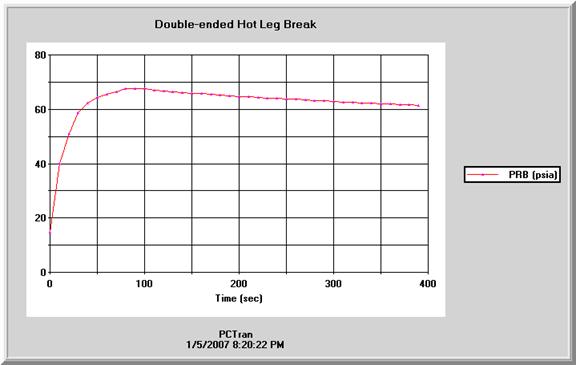

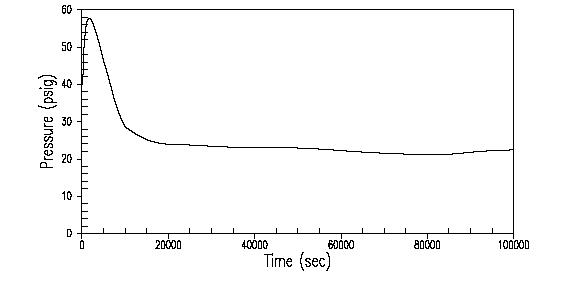

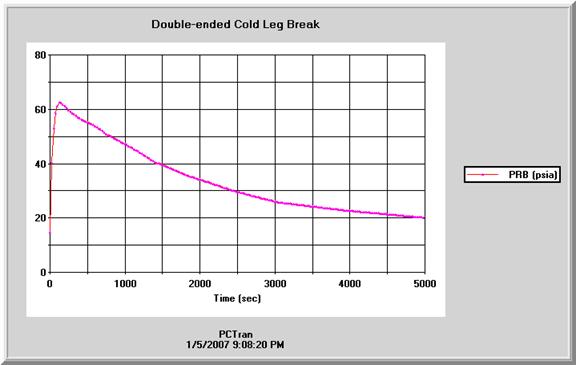

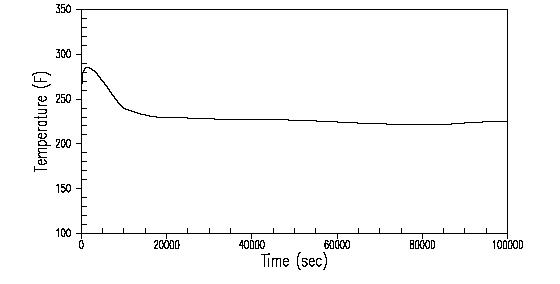

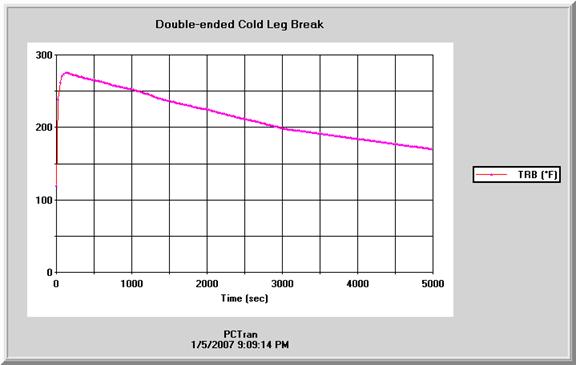

A 2000-cm2 cold leg break is initiated without any operator actions. The results of PXC and PCCS are shown below. They are in good agreement with FSER Case 6.2.1.1.

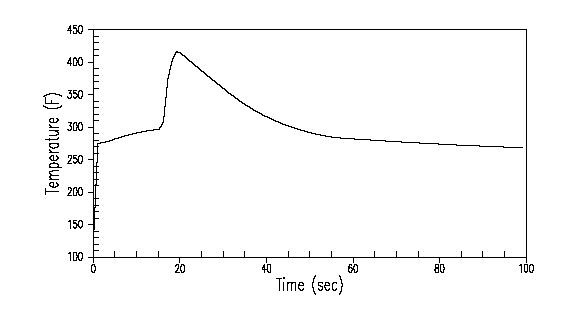

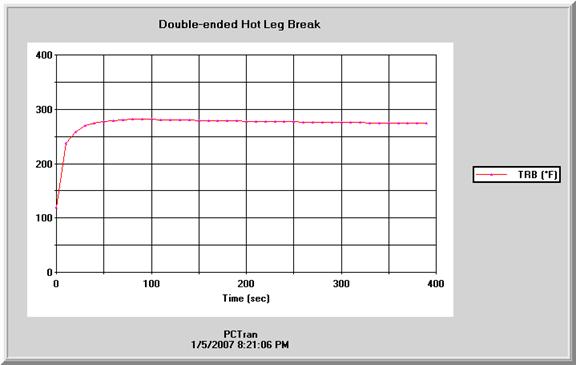

A 3000-cm2 hot leg break is initiated without any operator actions. The results of PXC and PCCS are shown below: