PCTRAN is the most successful desktop simulator for all types of light water nuclear reactors. It is specifically designed for many different plant types, including PWR, BWR, advanced AREVA EPR, Westinghouse AP1000, GE ABWR, and ESBWR. PCTRAN's simulation scope extends to severe accidents of BWR5 and RadPuff.for dose dispersion from all above. Since its first introduction in 1985 by Micro-Simulation Technology, PCTRAN has been selected by the IAEA as the training platform for its annual IAEA Simulators Workshop. Plant-specific models have been installed at nuclear power plants and institutions all over the world for practical application in training, analysis, probabilistic safety assessment, and emergency exercises.

Breaking News! Exercise NPP Defense Against Cyber Attack

A first-of-a kind kit for Nuclear Power Plant's defense against Cyber Attack is successfully developed. Our PCTRAN simulator on a single PC (Blue Team in a drill) is connected to a hacking Red Team's keyboard. One HDML-splitter line grants their monitor to peek into Blue's plant status and Digital Control System (DCS).

Red members are supposedly quite knowledgeable with the plant's design and operation. They may introduce critical malicious actions such as disturb feedwater supply to the steam generators, reset the low-water level reactor shutdown set point, disrupt the High-Pressure Injection to prevent coolant makeup, etc. Blue is supposed to correctly diagnose the event's cause by using regular Symptom- Oriented Procedures. They may not recognize it is from a hacker's attack at the beginning. Red may introduce further attacks to hamper Blue's actions. The plant condition may depredate further. Blue may decide to use NRC/NEI's so-called FLEX methodologies via alternate and diverse power and water supplies.

The event's end result will be either core-melt with dose release for Red win, or safe shutdown for Blue win. There is no pre-set scenario and result. Every time an exercise may end up an entire new sequence for post-exercise critique. Collection of all accumulated Lessons Learned form valuable training material for defense of future Design Basis Treats.

You may try it out using provided Free Download modules. You may also test force-on-force by setting up extra connections to separate keyboard and monitor for your hacker partner. The only drawback is the demo version are limited to runtime limit, so you won't see core-melt or worse. But he game can be played repeatedly for all kinds of cat-and-mouse chases.

Computerized Tool Against Cyber Attack at Nuclear Power Plant

For the first time, a computerized tool is developed against a potentially malicious cyber attach at a nuclear power plant. Our PC-based simulator PCTRAN was developed since 1985. Just now it is upgraded for training and exercise to meet the Design Basis Threat (DBT) requirement by regulatory agencies of nations in the world.

A PC installed of any version of our PWR or BWR plant specific models can work as the control room crew (Blue Team). The hackers (Red Team) could be situated next door during an exercise, or even in the same room connected by a separate keyboard and monitor with wires or wireless to the Blue's PC. These two teams should refrain from communicating with each other - assuming a force-on-force anonymous condition. Red does not require their own PC. Their keyboard and monitor are assumed to be the hacking devices already broken into Blue's Digital Control System (DCS). In addition, A detailed sample exercise with chronical plant condition displays and transient curves are presented by checking the link presented below. There are two scenarios: the first one Blue failed to diagnose the attack properly and react in time. The core melted for a Red win. Whereas in a re-run, Blue correctly examine the situation and mitigated properly. They won by maintaining the cool properly cooled and stable. Once a nuclear unit acquires this, they can run numerous and unlimited scenarios against in-house counterparts to build up own collection.

Following are new MP4 Video download in Chinese Narration:

National University of Singapore

The Singapore Nuclear Safety Initiative has acqured prototypes of HTR and offshore SMR simulators for training and research.

Malaysia Nuclear Agency

Nuclear Malaysia has acquired AP1000 for training at the Kuala Lumpur Headquarters.

EDF Hinkely Point Team train on New Simulator

to deliver PCTran®; a Micro-Simulation Technology© (MST), PC based simulator.

The course was attended by Campus Simulation instructors, nuclear graduates from Birmingham University and representative from STS Nuclear ©.

The simulator will enhance the Pressurised Water Generic Nuclear Fundamentals Course (GNF) developed and delivered by Campus to future nuclear engineers.

The training was used to highlight the capabilities of the simulator and the Campus Team were all very enthusiastic regarding the training potential that PCTran offers.

Campus Simulation Instructor said “I envisage the simulator being used to demonstrate basic nuclear and thermodynamic principles training. It also presents opportunities to develop people in fault and emergency scenario training in the future.”

STS Nuclear© (who assist Campus with GNF facilitation) was very impressed with the simulator and the practicalities that this PC based version offers over normal large scale fixed simulators.

The University graduates were equally impressed that PCTRAN was developed to operate on most PC’s, did not require large graphic cards, was easy to operate with minimal supervision and provided nuclear and thermodynamic principles.

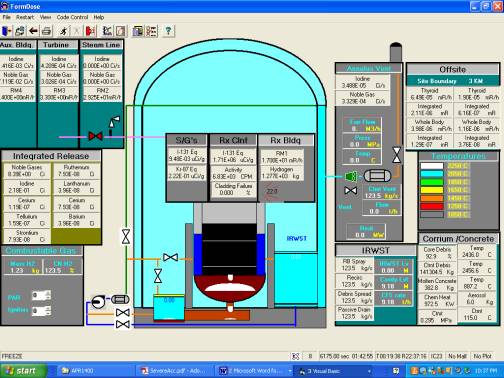

EDF Energy at Bridgwater, Somerset of UK has acquired the EPR model for its training program for Hinkley Point 3 project. The EPR includes a number of unique features to prevent or mitigate the effects of severe accidents:

- In-containment refueling water storage tank (IRWST),

- Severe accident heat removal system (SAHRS).

- Combustible gas control system (CGCS),

- Core-melt stabilization system

PCTRAN/EPR as a PC-based trainer, has all above systems and their respective functions modeled in dynamic simulation. As a result, students learn severe accidents and EPR’s unique system for mitigation.

Recent Licensees

Military Institute of Science and Technology of Bangladesh PCTRAN/VVER1200.

For training and education the Rooppur Project. In March of 2018 a three-day training class was conducted in its Dhaka campus. The entire faculty and student group attended.

Korea Hydro & Nuclear Corporation (KHNP) Center of Research Institute (CRI) has acquired PCTRAN KSNP and APR1400 severe accident models via FNC, Inc.

Atomic Energy Commision of Indonesia for HTR

Chattanooga State Technical Community College has acquired RadPuff for radiological dispersion projection.

Kennesaw State University for AP1000

Cuesta College for PWR4LP

Tohoku University of Japan has acquired PCTRA/BWR5

Kyushu University of Japan has acquired PCTRA/PWR 4-loop severe accident model vis CSA of Japan for its training and education.

King Abdu LaZiz University of Saudi Areabia has acquired generic PWR model for training and education for the kingdom's plan of constructing up to 16 power plants.

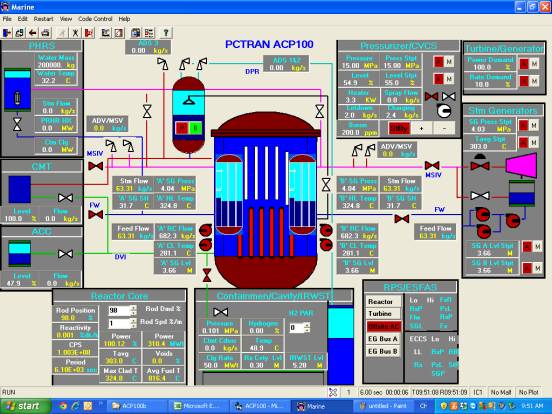

ACP100 is designed by China Central Nuclear Power Corporation – a 330 MWt pressurized water reactor with integral steam generators and passive core and containment cooling systems. In April of 2016 IAEA issued the world first final safety review report for the SMR. The unit can generate 100 MWe, provide 450 t/h district heating and up to120,000 t/day fresh water.

Our PCTRAN/ACP100 has an integral reactor vessel containing 16 once-through steam generators (OTSG) lumping into two, a pressurizer, pressure relief valves for the Automated Depressurization System (ADS), in-containment water tank, core makeup tank, accumulator, steel shell containment and passive residual heat removal system (PRHR) outside the containment.

Both manual and automatic controls are provided for normal operation, transient and accident mitigation.

The Russian VVER-1200 (NPP-2006 or AES-91) is the version currently offered for export. Right now there are active projects in China, India, Bangladesh, Bulgaria, Jordan and Egypt It is an evolution of the VVER-1000 with increased power output to about 1200 MWe (gross) and providing additional passive safety features. The PSAR (Preliminary Safety Analysis Safety Report) of model 392M under construction at the Novovoronezh NPP-II is used for developing and benchmark of the PCTRAN simulator.

Video

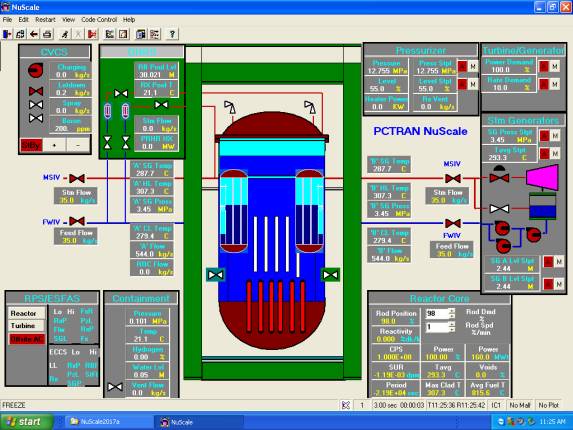

NuScale power module consists of a small 160 MWt reactor core housed with other primary system components in an integral reactor pressure vessel and surrounded by a steel containment vessel, which is immersed in a large pool of water. Above the core is a central hot riser tube, a helical coil steam generator surrounding the hot riser tube, and a pressurizer. The helical coil steam generator consists of two independent sets of tube bundles with separate feedwater inlet and steam outlet lines. A set of pressurizer heaters and sprays is located in the upper head of the vessel to provide pressure control.

PCTRAN simulator follows NuScale design closely by setting the module in the middle. The chemical and volume control system (CVCC), decay heat removal system (DHS), reactor protection system (RPS) and containment control panels are at left. The pressurizer, turbine and steam generators, and reactor core control are at right hand side.

The purpose of this PC-based simulator is not just for the control room operator training, but also for prospective clients in their evaluation of the technology. They learn how the passive-cooled inherent safe SMR works. In a quantitative and dynamic hand-on practice, the reactor performs well in startup, load control, electricity generation and desalination water production. They may also practice any combination of accident scenarios including feed and steam line breaks, SG tube leak, up to the most challenging Fukushima type station blackout up to 30 days – without any possibility of damage to the core or dose release.

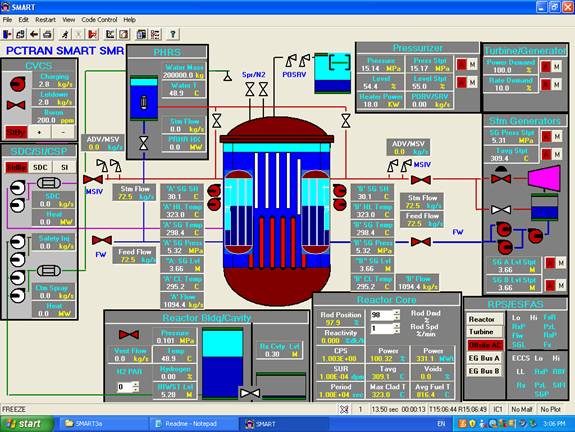

SMART is a 330 MWt pressurized water reactor with integral steam generators and advanced safety features. The unit designed by Korea Atomic Energy Research Institute (KAERI) for electricity generation (up to 110 MWe) as well as thermal applications such as seawater desalination.

The PC-based simulator PCTRAN for SMART was developed using experience gained on work for the Korean APR1400 and OPR1000. Both are licensed to Korea Institute of Nuclear Safety (KINS), Korea Electric Power Co (KEPCO), Korea Hydro and Nuclear Power (KHNP) and five universities in Korea. SMART has its unique in-vessel pressurizer, helical coil once-through-steam generators, and canned circulation pumps. It is equipped with both active and passive heat removal systems. In the event of a severe accident resulting hydrogen in the containment, there are passive auto-catalytic recombiners to reduce its concentration. They are all closely simulated for training and education.

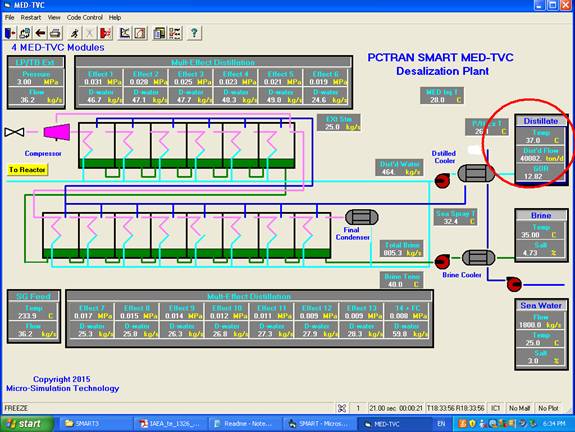

The reactor could use all its steam for electricity generation for a total of 110 MWe, or extract the steam at its low-pressure turbine to a MED-TVC plant for desalination. The electricity output will be reduced to 90 MWe with 40,000 tons of fresh water production per day. Combined the plant could support a 100,000 population city’s consumption.

The multiple effect distillation (MED) with thermal vapor compressor (TVC) has a gain output ratio (GOR) about 13 for the distilled water to the motive reactor steam.

A complete line of normal and accidental cases have been conducted. It includes normal startup, power escalation, shutdown and cool-down using normal HCSG and shutdown cooling system, loss of coolant accidents and station blackout (SBO) Fukushima type accident. Despite core damage and hydrogen generation is virtually impossible to occur, the simulator is capable to perform an intentional loss of passive RHR cooling event with hydrogen in the containment. Then start of the PAR suppresses the content to non-combustible level.

|